Description

*Due to the remedial purpose of these products they will very likely require the primary bore to be honed to fit barrel gas journals and are not designed to be “drop-in” components*

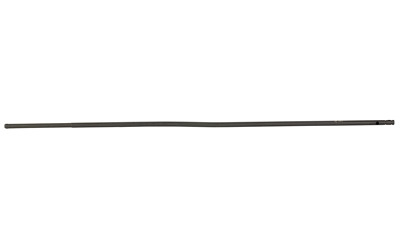

GOOD Gasblock .625” Remedial, armorer-fit block PN#772-625

GOOD gasblocks are armorer-fit gas blocks with key features to maximize gas seal, armorer ease-of-use, and compatibility with all handguard and barrel combinations. Available in both .625 and .750 nominal sizes they are made of heat-treated 4150 with a Manganese Phosphate finish. The switch to 4150 gives us trivially better strength compared to the more common 4140, but was primarily done to ensure a practically homogenous thermal expansion and contraction rates with common 4150CMV barrels. Both bores are strictly regulated during both the machining and finishing processes with the primary bore being matched to the low end of the adjacent barrel journal spec, allowing each gasblock to be fit for an unparalleled seal, even on “undersized” barrel journals. One of the more unique looking features, a pair of pre-located crosspinning flats have been added for either the included 1/8” coil pin or 1/8” solid pin. These allow the armorer to choose cross-pinning location based on need or preference. Lastly, a smaller diameter hole has been added at the front of the blocks. This feature was originally pioneered by the late Will Larson of Semper Paratus Arms and brought to production success by Roger Wang of Forward Controls and can be used with basic tool setups to remove a seized gastube by way of a 3/32” punch.

The resulting products are durable, backwards compatible, fixed blocks designed by an armorer for armorers to better troubleshoot and build duty-grade products for private and professional end users.

Weight:

34g/1.2oz (.625)

37g/1.3oz (.750)

Hardware:

(2) C45 10-32×1/8”, (1) Stainless 5/64”x1/4” roll pin, (1) Stainless 1/8”x7/16” coil pin and (1) 4140 1/8”x7/16” solid pin